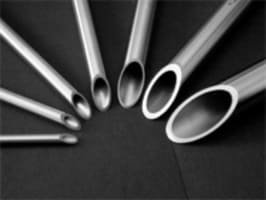

Cleaned tubes

To obtain grease and oil free surfaces, specialized chemical treatments are often required in the process and petrochemical industry. Our straight tubes are already from a high clean level (“standard industrial clean”), but for certain applications we recommend extra chemically treatment to receive contamination free tubes in order to prevent costly equipment downtime or failure. The most common way to chemically treat our tubes (“Ultra clean”) is required for tube applications where oxygen will be used or transported. The cleaned tubes will be packed with caps on the ends and in polyethylene heat sealed bags. Upon customers request any type of cleaning can be arranged from degreasing, pickling & passivation to electropolishing which is used to remove all oil, grease, dirt, finger prints and/or any other organic residues even to the requirements of ASTM G93 level A. After cleaning an intensive inspection is carried out to issue a cleaning test certificate.

Our seamless coil tubes are even certified to the cleanliness requirements of ASTM A632 S3.1.2, thermocouple clean on the inside diameter defined as being free of all drawing compounds, carbon, dirt, dust, visible surface oxides, scale, and other contaminants. This is a verification test using a solvent-saturated cloth which is passed through the tubing. Unacceptable results lead to additional cleaning operations until tubing passes the thermocouple clean requirements, the ends are protected with polyethylene caps and the coils are packed on wooden or plastic spools.